Materials for custom-made glasses

Custom-made and high-end materials have long been two sides of the same coin. While luxury has moved with the times, old spectacle-making skills still endure. Wood and rare metals feature, of course, but other vibrant and compelling fine materials are transformed into frames in the expert hands of the craftspeople who make spectacles.

Let us show you what is best, most precious and especially most unique in custom-made – as each piece is subtly different from all the rest.

The potential of ivory

No, we’re not going to extol the virtues of elephants’ tusks. While this material excited numerous collectors, elephants had an entirely different view of the matter. The ivory trade has been prohibited since 1989 to protect the species.

These prehistoric creatures, close relatives of today’s Asian elephants, lived in African and Eurasia. Most bones are found in Siberia, though, and these include tusks.

© Yvan Vollmy

Yvan Vollmy, a Swiss optician and spectacle-maker, is one of a very few who work with mammoth ivory. Each piece is carefully designed for a glasses-wearer.

© Yvan Vollmy

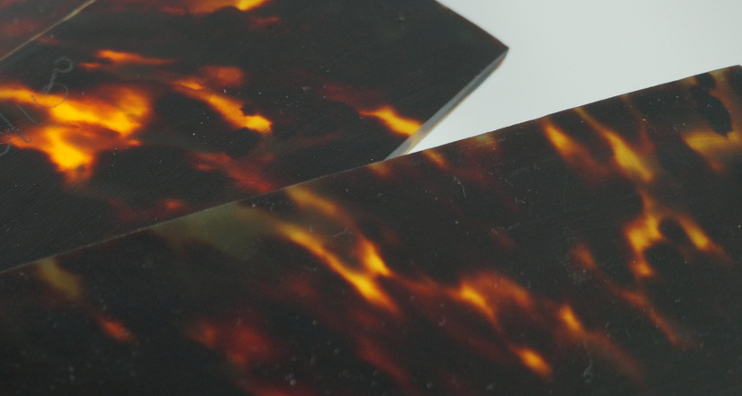

The slow waltz of tortoiseshell workers

For many, the turtle shell is the perfect material to be used in the making of eyewear. This one hundred percent natural material has peerless mechanical properties. The turtle shell, made of keratin, is surprisingly elastic. It adapts to the face shape and uses its heat while being hypoallergenic. The self-grafting ability of the Hawksbill turtle shell makes it the only one suitable for producing objects.

Working with tortoiseshell is a fine art that few have mastered. There are a few spectacle-makers, though, like the craftspeople of Établissements Dorillat, in France, who are preserving these traditional skills.

© Dorillat

Only once this essential preparatory work is complete does the craftsman begin to shape their frames, a step that requires patience and precision.

Every curve, every angle, every last part of the glasses must be drawn, cut out, and then carefully polished. The result is the lustrous glow that is so characteristic of tortoiseshell.

Then, all that remains is to fit and adjust the frames to make them perfect for the face for which they were made.

© Dorillat

Since hunting turtles is now prohibited, it is impossible to purchase new shells. However, it is still legal to make use of pre-1976 stockpiles.

Horn in abundance

A German designer is working on “natural materials”, including water buffalo horn. Hoffmann Natural Eyewear is specialized in bespoke horn-rimmed eyewear, which it makes to measure in its workshop in Germany.

From the most commonplace materials such as acetate to the most striking, such as shagreen or mammoth ivory, custom-made offers near-limitless possibilities. Luxury spectacle-makers prove on a daily basis that their art is in no danger of dying out, as no technology could replace the practiced hand of a skilled craftsperson who works with love and care, and respect for the materials they use.